Searching for a high-performance abrasion-resistant steel that balances extreme hardness with dependable toughness? rockstar 450 is engineered for industries that operate in severe wear environments and demand longer service life with reduced maintenance costs. Buyers across mining, construction, and material handling sectors consistently choose rockstar 450 because it delivers superior wear resistance, predictable performance, and excellent value throughout the equipment lifecycle.

Searching for a high-performance abrasion-resistant steel that balances extreme hardness with dependable toughness? rockstar 450 is engineered for industries that operate in severe wear environments and demand longer service life with reduced maintenance costs. Buyers across mining, construction, and material handling sectors consistently choose rockstar 450 because it delivers superior wear resistance, predictable performance, and excellent value throughout the equipment lifecycle.

Why Buyers Prefer rockstar 450

In today’s competitive industrial landscape, buyers look beyond price and focus on performance, durability, and long-term savings. Rockstar 450 answers these expectations by offering higher hardness than standard AR grades while still maintaining good impact resistance. As a result, equipment lasts longer, downtime decreases, and operating efficiency improves.

Moreover, rockstar wear steel performs reliably under continuous abrasion, sliding wear, and moderate impact. This combination makes it an ideal choice for demanding applications where frequent replacement of liners and wear parts becomes costly.

Buyers prefer rockstar 450 because it delivers:

-

Higher hardness for extended wear life

-

Excellent resistance to abrasion and surface wear

-

Consistent mechanical properties across the plate

-

Reduced maintenance and replacement frequency

-

Strong performance in abrasive and impact-loaded environments

-

Good weldability with proper procedures

-

Improved productivity and lower lifecycle costs

Because of these benefits, rockstar 450 has become a trusted material for OEMs, fabricators, and maintenance teams worldwide.

Technical Specifications of rockstar 450

A clear understanding of technical specifications helps buyers select the right material for long-term performance.

Chemical Composition (Typical %)

-

Carbon (C): 0.28 – 0.35

-

Manganese (Mn): 1.20 – 1.70

-

Silicon (Si): 0.20 – 0.50

-

Chromium (Cr): 0.60 – 1.50

-

Nickel (Ni): 0.20 – 0.60

-

Molybdenum (Mo): 0.20 – 0.40

-

Boron (B): Max 0.005

This carefully controlled alloy composition provides high hardness while preserving structural integrity and toughness.

Mechanical Properties

-

Hardness: 420 – 480 HBW

-

Yield Strength: ≥ 1100 MPa (typical)

-

Tensile Strength: 1300 – 1500 MPa

-

Elongation: 8 – 12%

These mechanical properties make rockstar 450 ideal for heavy-duty wear applications where abrasion is the primary failure mode.

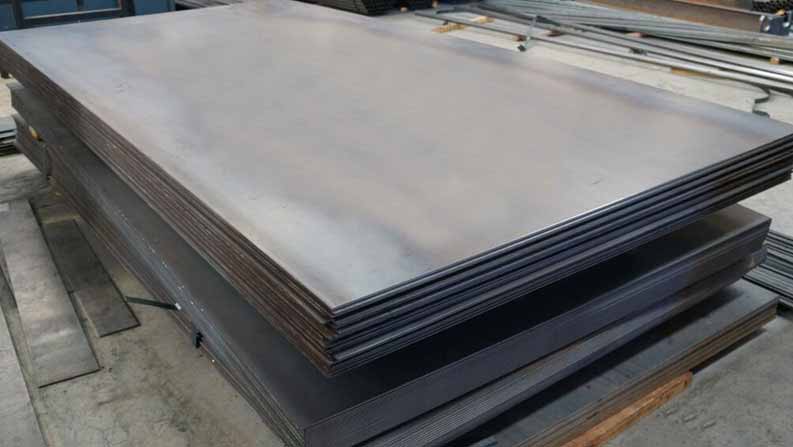

Available Forms

-

Abrasion-resistant steel plates

-

Cut-to-size wear plates

-

Profile-cut and fabricated components

Applications

rockstar 450 is widely used in:

-

Mining and quarrying machinery

-

Dump truck bodies and excavator buckets

-

Hoppers, chutes, and liners

-

Cement, aggregate, and coal handling plants

-

Construction and earthmoving equipment

-

Recycling and bulk material processing systems

International Standards & Equivalents

To ensure global acceptance and buyer confidence, rockstar 450 aligns with internationally recognized wear-resistant steel standards:

-

UNS: No direct UNS number (abrasion-resistant steel category)

-

ASTM: ASTM A832 / AR450 (equivalent wear-grade reference)

-

ASME: ASME SA832

-

DIN / EN: EN 10051, EN 10204 (abrasion-resistant steel references)

These standards confirm quality consistency, traceability, and suitability for critical industrial applications.

Regional Buyer Demand Focus

-

India

-

High demand in mining, cement, infrastructure, and power sectors

-

-

Germany

-

Preferred for precision-engineered wear parts and heavy machinery

-

-

UK

-

Widely used in recycling, quarrying, and aggregate industries

-

-

UAE

-

Strong usage in construction, ports, and material handling operations

-

Why Buyers Partner with Vandan Steel & Engg.co

Selecting the right supplier is just as important as choosing the right steel grade. Buyers partner with Vandan Steel & Engg.co because we focus on reliability, transparency, and long-term value.

-

Mill Test Certificates (MTCs) for full traceability

-

Flexible MOQs to support both small and bulk orders

-

Efficient domestic and international logistics support

-

Technical guidance on grade selection, welding, and fabrication

-

Consistent quality, competitive pricing, and timely delivery

Our buyer-focused approach simplifies procurement and ensures dependable supply for critical projects.

Secure Your rockstar 450 Supply Today

If your operations demand superior abrasion resistance, extended service life, and reduced maintenance costs, rockstar 450 is the ideal solution. Partner with a trusted supplier who understands your performance and delivery requirements.

Vandan Steel & Engg.co

359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004.

???? +91-8828813630

✉️ [email protected]

Contact us today to discuss your requirements and source high-quality rockstar 450 plates with complete technical support and reliable global delivery.